Application of Linear Unit Dynact

Axis type: MR 10 S SM R S1200 L2000 S1 0000 M0

Size 25-110 - Rack & Pinion driven – Stroke 1200mm – Single carriage

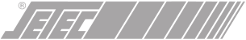

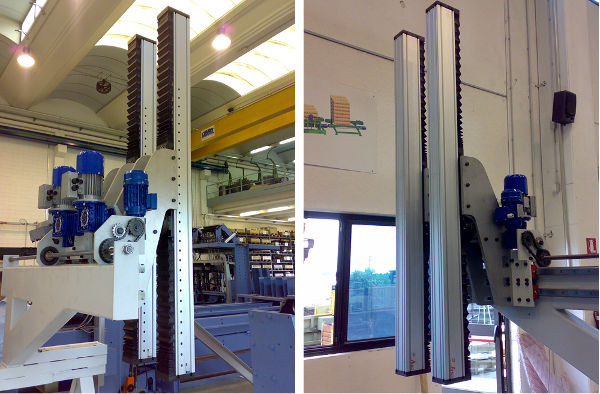

The rack & pinion linear module M 110 is vertically mounted and fixed to the carpentry. At the bottom of the system a frame with a brush is fixed (diameter 300mm and width of 500mm).

The axis M 110 is positionned over the mould and when operated the 2 units go down and start brushing the mould to clean it. It can translate sideways in order to find the right position thanks to two Hiwin HGR 35rails, four HGW35 blocks and a trapezoidal screw.

In the picture we can see how the rotating brush is connected to both units and how the two 2 rack&pinion linear modules are driven by 1 three-phase motorgearbox. There will be a possible evolution of this machine with brushless motor and planetary gearbox because some application might need a reduction of the duty cycle. For example the Oring mould.

Before the customer had a pneumatical cylinder installed which was working vertically to clean the mould but, of course, the result was not accurate and slower.