The process on the thermoforming line starts with a section where the film is unwind, then it progress horizontally thanks to a pair of grippers which are pulling it.

This progress is made thanks to the high accuracy Electric Linear Actuator INDACT ISOMOVE tipo: IM80, which is controlling the movement of the grippers, which are sliding horizzontaly on recirculating bushes.

During the progress, the film stops under different forming stations.

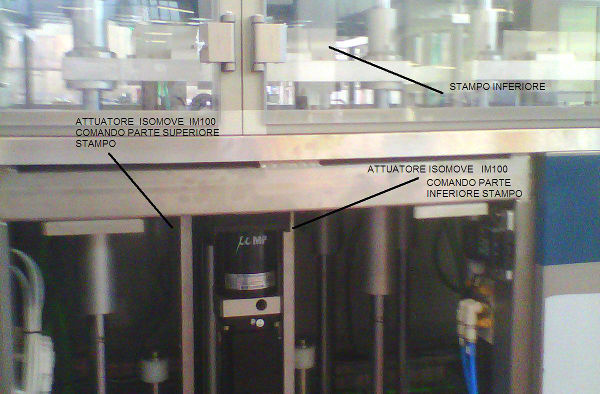

Every station is composed by a press – like in the picture – divided in 2 parts, a upper part and a lower one sliding vertically independently guided by cemented shafts and between these 2 sections a plastic film is thermoformed.

Every section is moved by a Setec Actuator INDACT ISOMOVE. This means that on every mould there are 2 Electromechanical Cylinders (one in the upper part and the other one in the lower part).

The movement with electromechanical cylinder allow to control the approach of the 2 sections of the mould (with a motion profile acceleration-deceleration) and the final pressure, whose control is not possible with pneumatic systems.

The pressure when the mould is closed reaches 1200-1500 kg and it is hold for 15-20 s.

According to the type of thermoforming there are 2 or 3 controlled stations.

This application has been realized with:

- Electromechanical Cylinder Setec INDACT ISOMOVE type: IM80-25-500 -D stroke 500 for the control of the horizontal film progress;

- Electromechanical Cylinder Setec INDACT ISOMOVE type: IM100-20-200-R stroke 200 for the mould control.

The market where these lines are adressed is the food sector. In the specific we have installed them on machines which produce yoghurts pots, chocolate and capsules for coffee machines.